What Are Woven Badges and How Are They Made?

Woven badges are a higher-quality alternative to traditional embroidered patches, gaining popularity in uniform and merchandise applications. These sophisticated identification markers deliver exceptional detail and a refined aesthetic that embroidery simply cannot match. Businesses, organizations, and brands increasingly choose woven badges when precision and professional appearance take priority. The smooth, flat construction sets them apart from conventional patches, making them particularly suitable for modern branding requirements where crisp logos and fine text are essential.

The Weaving Process Behind Premium Badge Production

Production of Woven badges relies on specialized weaving machines that interlace thin threads to create a tight, flat surface. The process mirrors traditional textile weaving but operates on a miniature scale with remarkable precision. These machines work by interlocking warp threads with weft threads in a controlled pattern that forms the desired design.

The machinery used in woven badge production functions similarly to computer-controlled looms, translating digital designs into physical patches through programmed thread placement. Each thread follows a specific path, building the image row by row with exacting accuracy. This method allows manufacturers to incorporate multiple colors within a single badge, with thread changes happening automatically as the weaving progresses.

Thread thickness plays a crucial role in the final product quality. Woven badges typically use threads measuring 50-75 denier, significantly finer than the 40-weight threads common in embroidery. This thin thread construction enables the creation of detailed imagery that would be impossible with thicker materials. The tight weave density—often exceeding 100 threads per inch—ensures designs remain sharp and legible even at small sizes.

Texture and Appearance: A Distinct Departure from Embroidery

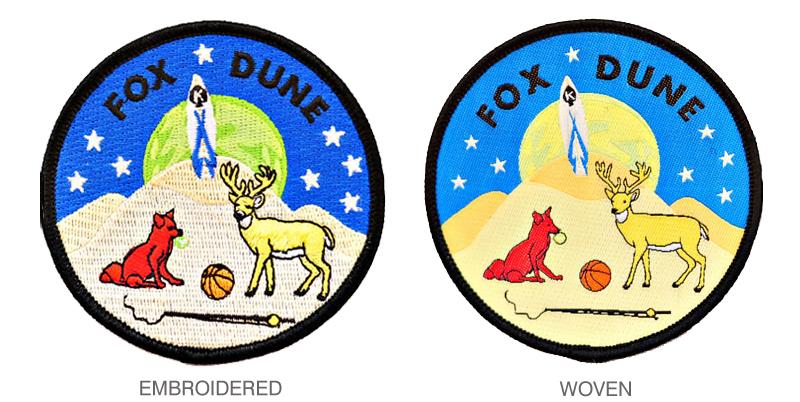

The most noticeable difference between woven and embroidered badges lies in their surface characteristics. Woven badges present a completely flat profile with no raised elements, creating a sleek, modern appearance. When you run your fingers across a woven badge, the surface feels smooth and uniform, similar to a tightly woven fabric ribbon.

Embroidered badges, by contrast, feature a dimensional quality with threads raised above the backing material. This creates texture and depth that some find appealing for traditional applications.

How Do Woven Badges Differ From Embroidered Badges?

What Makes Thread Thickness the Defining Difference?

The main difference between woven and embroidered badges is the thickness of the threads used, which creates very different results. Embroidered badges use thick threads—typically 40-60 weight polyester or rayon—that are sewn onto a backing material, creating raised, dimensional stitches. In fact, the lettering on embroidered badges can often appear bulky due to this thread thickness. On the other hand, woven badges employ threads as fine as 75-100 denier polyester, interlaced on specialized looms to produce an almost fabric-like surface.

This difference in thread thickness directly affects how the final product looks and feels. Embroidered badges have visible stitch patterns with a tactile, raised surface that you can feel with your fingertips. The thick threads create a robust, textured finish that stands proud of the backing material. Woven badges have a nearly flat profile with threads so tightly interlaced that individual strands become difficult to distinguish, resulting in a smooth, almost printed appearance.

The contrast in texture becomes immediately obvious when you handle both types of badges. Embroidered patches feel substantial and three-dimensional, with each stitch contributing to a handcrafted aesthetic. Woven patches feel closer to woven fabric labels found in high-end clothing, offering a sleek, refined touch that sits flush against garments without creating bulk.

Can Woven Badges Handle Intricate Design Details Better?

Woven badges excel at capturing fine details and small text that would be impossible with embroidery. The thin threads allow for design detail reproduction down to 0.5mm line widths, making them ideal for complex logos featuring intricate patterns, small lettering, or detailed imagery. Corporate logos with fine serif fonts, technical diagrams, or designs with multiple thin lines translate beautifully onto woven badges.

Embroidered badges struggle with text smaller than 3mm in height because thick threads cannot form legible characters at that scale. The minimum stitch size limitations mean fine details either become muddled or require simplification during the digitizing process. However, woven badges can reproduce text as small as 1.5mm tall while maintaining clarity and readability, opening possibilities for including website URLs, taglines, or detailed certification marks.

Why Are Woven Badges Considered a Premium Option for Uniforms and Merch?

What makes woven badges stand out in terms of quality and finish?

Woven badges deliver a level of smoothness and precision that elevates them above standard identification options. The tight weaving process creates an ultra-flat surface where every thread sits perfectly aligned, eliminating the bumpy texture common in other badge types. This precision allows designers to reproduce complex logos with sharp edges and clean lines that maintain their integrity even at small sizes.

The manufacturing technique behind premium badges ensures consistent quality across large production runs. Each badge emerges from the loom with identical thread placement and color distribution, making them ideal for corporate uniforms where brand consistency matters. Companies in hospitality, aviation, and corporate sectors increasingly specify woven badges because they project professionalism through their refined appearance.

Sleek design capabilities extend beyond simple logos. Woven badges can incorporate:

- Multiple color gradients within a single design

- Text as small as 6-point font that remains legible

- Intricate border details and fine line work

- Photorealistic elements that capture brand essence

The smooth surface also resists snagging and pilling better than raised embroidery, maintaining its pristine appearance through repeated wear and washing cycles.

How does the physical feel of woven patches benefit garment applications?

Lightweight patches offer practical advantages that matter in everyday wear. A woven badge typically weighs 40-60% less than its embroidered equivalent, reducing strain on delicate fabrics and preventing sagging over time. This weight difference becomes noticeable on items like silk blouses, lightweight polo shirts, and performance athletic wear where bulk disrupts the garment’s drape.

The flexibility of woven construction allows patches to move naturally with fabric rather than creating stiff, board-like areas. When applied to jackets, the badge bends with the wearer’s movements instead of creating uncomfortable pressure points. Hat applications particularly benefit from this flexibility, as woven badges conform to curved surfaces without warping or creating gaps at the edges.

Delicate fabrics that would pucker or distort under heavy embroidery accept woven badges without structural compromise. Designers working with:

- Cashmere and merino wool blends

- Lightweight cottons such as voile or lawn

- Fine knits including jersey or ribbing

can confidently choose woven patches as a solution that enhances both aesthetics and functionality.

What Design Possibilities Do Woven Badges Offer That Embroidery Cannot?

1. Photorealistic Images

Can woven badges truly reproduce photorealistic images? Yes, the ultra-thin threads used in weaving allow for complex imagery that embroidery simply cannot match. Traditional embroidered patches rely on thick threads that create visible gaps between stitches, limiting their ability to blend colors seamlessly. Woven badges eliminate this constraint by interlacing thousands of fine threads per square inch, creating a tight weave that mimics the resolution of printed images. This capability makes photorealistic patches achievable for brands wanting to reproduce detailed photographs, portraits, or complex artwork on their uniforms and merchandise.

2. Color Variations and Gradients

The technique excels at rendering color variations and subtle gradients that would appear blocky or undefined in embroidery. A sunset scene, for instance, transitions smoothly from orange to purple in a woven badge, while an embroidered version would show distinct color blocks. Product logos featuring metallic sheens, shadows, or dimensional effects translate accurately through weaving. Companies in industries like automotive, technology, and hospitality benefit from this precision when their brand identity includes sophisticated visual elements that demand faithful reproduction.

3. Intricate Designs

Intricate designs featuring multiple small components remain legible and distinct in woven format. Consider a company logo with overlapping geometric shapes, fine line work, or detailed mascot illustrations—these elements maintain their integrity without the thread buildup that embroidery creates. The flat surface prevents shadowing or distortion that raised stitching might introduce.

4. Crisp Lettering

How small can text be on a woven badge while remaining readable? Woven badges achieve crisp lettering down to approximately 1-2mm in height, whereas embroidered text typically requires 3-4mm minimum for clarity. This difference proves critical for badges displaying website URLs, certification numbers, or taglines beneath primary logos. The precision of woven threads ensures each letter maintains sharp edges and proper spacing, preventing the fuzzy appearance that occurs when embroidery thread thickness exceeds the character size.

5. Expanded Font Choices

Font choices expand significantly with weaving technology. Serif fonts with delicate details, script fonts with flowing connections, and condensed typefaces all reproduce accurately. Legal text, safety warnings, or multi-language information fits comfortably on smaller badge surfaces without sacrificing readability. Professional services firms and medical organizations often rely on these capabilities to convey essential information succinctly while maintaining their brand aesthetic. Check out more about Why a Custom Car Air Freshener Is One of the Most Underrated Branding Tools.

When Should One Choose Embroidered Badges Over Woven Ones?

Does embroidery still have a place in modern badge design? Yes, it does! Embroidered badges are great for specific situations where their unique qualities offer clear benefits over woven badges, especially in tough environments and traditional settings.

Why Choose Embroidered Badges?

Here are some reasons why you might want to consider using embroidered badges:

- Outdoor Durability: Embroidered badges are built to last in outdoor settings. The thick threads used in embroidery create a sturdy surface that can handle rough weather, frequent washing, and physical wear better than woven badges. This makes them ideal for military units, outdoor recreation programs, and work uniforms exposed to tough conditions.

- Textured Patches: Many organizations appreciate the tactile quality of embroidered patches. The raised surface of embroidery adds a three-dimensional effect that customers can feel, giving uniforms and merchandise a premium, handcrafted touch. Sports teams, motorcycle clubs, and heritage brands often prefer this authentic look that embroidery provides.

- Design Flexibility: Embroidery works well for designs with simple logos, bold text, traditional aesthetics, and high-contrast elements. If your logo has thick lines and minimal detail or if you need large font sizes for readability, embroidery is a suitable choice.

When to Opt for Woven Badges?

While embroidered badges have their advantages, there are situations where woven badges may be more appropriate:

- Intricate Designs: If your logo or design contains fine details that require precision, woven badges can capture those intricacies better than embroidery.

- Large Quantities: For projects requiring large quantities (typically over 100 pieces), woven badges may be more cost-effective due to economies of scale.

- Lightweight Applications: In cases where weight is a concern (e.g., lightweight garments), woven badges tend to be lighter than their embroidered counterparts.

Budget Considerations

If you’re working with a limited budget or need smaller quantities (around 50-100 pieces), embroidery may be the more economical option as its setup costs are generally lower compared to woven alternatives.

Turnaround Time

When time is of the essence, embroidery often offers quicker production times since its processes typically require less time than weaving.

In summary, both embroidered and woven badges have their own strengths depending on factors such as design complexity, quantity requirements, budget constraints, and turnaround times. Assessing these aspects will help you determine which type aligns best with your specific needs.

How Do Woven Badges Compare to Sublimation Patches?

Sublimation patches vs woven badges differ fundamentally in their production methods and visual capabilities.

Production Methods

Sublimation technology uses heat transfer to infuse dye directly into polyester fabric, creating full-color designs with unlimited color options and photographic quality. The process involves printing a design onto special transfer paper, then using heat and pressure to convert the ink into gas that bonds with the fabric fibers. This results in vibrant, smooth patches with no texture variation across the surface.

Woven badges create their imagery through interlaced threads, limiting color options typically to 8-12 shades per design. The weaving process produces a textile feel with subtle texture, while sublimation delivers a completely flat, print-like appearance. This makes sublimation ideal for artwork-heavy designs where color accuracy matters most.

Visual Output

The visual output between these two options reveals distinct characteristics. Sublimation patches excel at reproducing:

- Gradient effects and color blending

- High-resolution photographs and complex artwork

- Designs requiring dozens of colors without additional cost

- Smooth, glossy finishes that feel printed rather than woven

Woven badges maintain their appearance longer because the colored threads themselves form the design—there’s no printed layer to fade or peel away.

Durability Differences

Durability differences become apparent with regular use and washing. Sublimation patches can fade over time, especially when exposed to direct sunlight or harsh detergents, since the dye sits within the fabric rather than on top. The heat transfer bond may weaken with repeated laundering cycles. Woven badges maintain their appearance longer because the colored threads themselves form the design—there’s no printed layer to fade or peel away.

Fabric Compatibility

Fabric compatibility also separates these options. Sublimation requires polyester content to work effectively, making it unsuitable for cotton or natural fiber garments. Woven badges attach to any fabric type through sewing or backing adhesives. The raised edges and textile construction of woven patches provide a more traditional, premium feel compared to the flat, modern aesthetic of sublimation patches.

What Are the Cost and Production Time Considerations For Choosing Woven Badges?

How Much Do Woven Badges Cost Compared to Embroidered Ones?

Woven badge cost typically runs higher than embroidered alternatives, especially at lower order quantities. The weaving process requires specialized machinery and precise setup that increases initial expenses. Businesses ordering 50-100 badges may pay 30-50% more per unit compared to embroidered options.

The complexity of the weaving method drives these price differences. Each badge requires careful thread selection, loom configuration, and quality control checks that embroidery doesn’t demand to the same degree. The thin threads used in woven badges—often as fine as 0.1mm—require delicate handling and slower production speeds to maintain the crisp detail that makes these badges premium.

How Does Quantity Pricing Affect Your Investment?

Quantity pricing works favorably for woven badges once you reach higher volumes. Orders of 500+ units often see per-badge costs drop significantly, sometimes matching or approaching embroidered badge pricing. The setup costs get distributed across more units, making bulk orders economically sensible.

Small businesses and startups face a decision point here. Paying premium prices for 100 woven badges might strain budgets, yet the professional appearance can justify the investment for client-facing uniforms or high-end merchandise. Many suppliers offer tiered pricing structures:

- 1-100 units: Premium pricing ($3-8 per badge)

- 100-500 units: Moderate pricing ($2-5 per badge)

- 500+ units: Competitive pricing ($1.50-3 per badge)

These ranges vary based on size, color count, and backing options selected.

What Should You Expect for Production Time?

Production time for woven badges extends beyond embroidered alternatives by 3-7 days on average. Standard turnaround sits at 10-15 business days from artwork approval to delivery, while embroidered badges often ship within 7-10 days. Rush orders are available but add 20-40% to costs.

The extended timeline reflects the meticulous nature of weaving. Thread preparation, loom setup, weaving, cutting, and finishing each require dedicated time. Quality control inspections happen at multiple stages to ensure the fine details remain sharp and consistent throughout production.